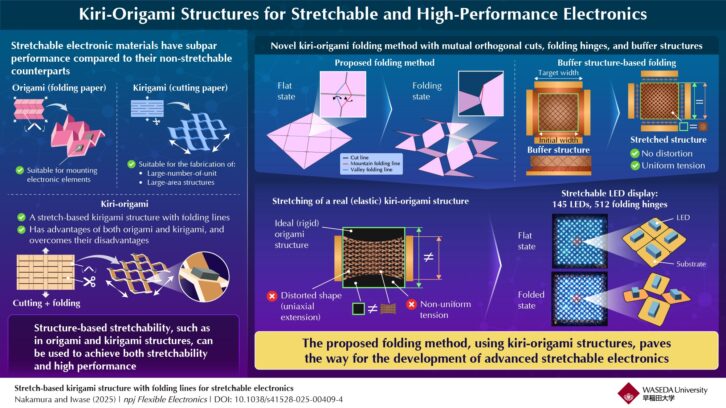

Researchers at Waseda University, Japan, have created a novel kiri-origami structure that combines folding and cutting techniques to produce high-performance stretchable electronics using traditionally rigid materials. The approach was demonstrated using a stretchable display with over 500 hinges and 145 LEDs, which maintained performance even after repeated deformation.

A kiri-origami structure is a hybrid design that combines two traditional Japanese techniques – origami (folding) and kirigami (cutting) – to create flexible, stretchable, and reconfigurable materials, or devices.

A kiri-origami structure is a hybrid design that combines two traditional Japanese techniques – origami (folding) and kirigami (cutting) – to create flexible, stretchable, and reconfigurable materials, or devices.

Led by Professor Eiji Iwase and researcher Nagi Nakamura, the team designed a hybrid origami-kirigami pattern with orthogonal cuts and triangular folding joints. This structure allows rigid electronic components to be mounted on panels that rise and rotate when stretched, enabling both structural flexibility and electronic integrity.

The technique overcomes the longstanding trade-off between electronic performance and flexibility, enabling new applications in wearables, curved displays, and soft robotics.

To address deformation issues in real-world materials, the researchers introduced elastic buffer structures that ensure uniform tension and controlled stretching.

Iwase said: “Our method bridges the gap between flexibility and function. It allows complex, large-area stretchable electronics without compromising performance.”

The findings were published in npj Flexible Electronics (June 2025), and the technique is expected to accelerate development in next-gen electronics, healthcare devices, and assistive robotics.