Nissan Formula E Team, part of the ABB FIA Formula E World Championship, has developed a realistic simulation with a 180-degree wraparound video image comprising of three projectors. Nissan’s team needed a calibration solution to blend their projectors together that fit their existing system design and offered improvements over its existing automated tools, and selected Scalable Display Technologies to automatically calibrate the geometry, colour and intensity of images – so enhancing the quality of the image and the realignment time of the simulator.

Scalable offered a unique technical advantage for Nissan Formula E Team’s simulator, not only in its accuracy and ease of use but also in its flexibility to adapt to the system architecture and screen geometry. Simulations are most effective when the driver’s field of view is completely immersed, which requires rendering power from the content databases. Nissan Formula E Team used multiple PCs for each projector to improve the graphic quality and rendering performance of the simulation. As a result, Scalable allowed the separate PCs to be treated as one consistent display.

Scalable’s groundbreaking software uses cameras to automatically calibrate multiple projectors images into a single seamless display. The cameras capture data during a collection sequence to create a series of mesh files that contain data for the display geometry, color, brightness, and overlaps. The cameras are used to realign the image at the click of a button or set to run regularly on a schedule, ensuring Nissan Formula E Team’s drivers always have access to the simulator and the image is forever simulation-ready.

Scalable’s groundbreaking software uses cameras to automatically calibrate multiple projectors images into a single seamless display. The cameras capture data during a collection sequence to create a series of mesh files that contain data for the display geometry, color, brightness, and overlaps. The cameras are used to realign the image at the click of a button or set to run regularly on a schedule, ensuring Nissan Formula E Team’s drivers always have access to the simulator and the image is forever simulation-ready.

“We selected Scalable Display Technologies to replace our old warp and blend technology system, ” said Dorian Boisdron, director, Nissan Formula E Team. “Our previous system was not robust and was time-consuming. Particularly for this application, the visuals must be flawless. We required a solution that is not only easy-to-use, but reliable and accurate.”

ABB FIA Formula E World Championship is the world’s first and only single-seater motorsport championship for electric race cars. Established in 2014, Formula E combines unbeatable cutting-edge technology, global circuits, best-in-class teams and drivers and unpredictable competition to create the world’s greenest sport. Since debuting on the grounds of the Olympic Park in Beijing in 2014, Formula E has grown into a global entertainment brand with motorsport at its heart. Today, Formula E continues to drive innovations in technology and mobility through collaborations with many of the world’s most competitive automotive manufacturers.

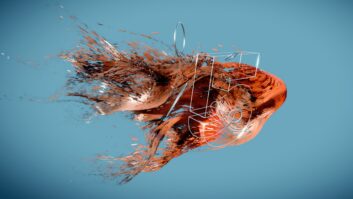

Driving simulators are an essential tool for professional racing teams to train their drivers and gain insights into their driving techniques. Data collected by Formula E racing cars, tracks and sensors from actual races are fed into these simulators to create training exercises that are realistic and repeatable. Motorsport teams with simulators can train year-round and from anywhere in the world. Driving simulators provide an important edge to any driver looking to shave off that last tenth of a second at the checkered flag.

“As a race team operating in the FIA Formula E World Championship, we use a driving simulator to train our drivers and to prepare the team for each race,” explained Boisdron. “The real-world tracks are scanned with lasers and added into the simulation software within an inch of perfect accuracy. We need to create a solution with pristine imagery to give our drivers an accurate representation of what they would normally see from a racecar to understand the sensation of speed, position on track, braking points and other dynamics.

“As a race team operating in the FIA Formula E World Championship, we use a driving simulator to train our drivers and to prepare the team for each race,” explained Boisdron. “The real-world tracks are scanned with lasers and added into the simulation software within an inch of perfect accuracy. We need to create a solution with pristine imagery to give our drivers an accurate representation of what they would normally see from a racecar to understand the sensation of speed, position on track, braking points and other dynamics.

Since 2004, Scalable has provided industry-leading applications, using machine vision algorithms to create a simple-to-use, cost-effective solution for warping and blending high- resolution display. There are no limits to the size, shape or resolution of the displays that can be created with Scalable’s software.