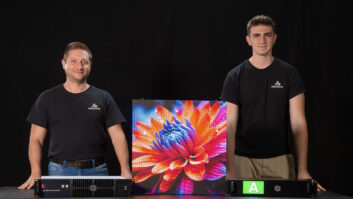

Following the warm response it received at ISE 2017, VTRON’s VLED-II second generation videowall has now officially been launched. The VLED-II series uses COB (chip-on-board) technology, whereby the LED diodes are directly encapsulated into the PCB to give a very smooth surface. VTRON’s own matt layer is said to give extraordinary protection and an enhanced contrast ratio.

VLED-II offers a seamless canvas and is claimed to provide more comfortable viewing experience, higher reliability, three ‘anti-properties’ (anti-collision, anti-static, water and dust resistant to IP5X) and the lowest dead pixel rate. The series is available in 1.2mm, 1.5mm and 1.8mm pixel pitches.

The second-generation LEDs in a VLED-II unit are packed densely in each module to form a surface of light sources and hence a more uniform image without glare, says VTRON. Modules can be tiled together snugly to form a seamless image.

VTRON’s matte coating is claimed to offer softer images, and reduce light radiation, moiré and glare, while still displaying fine image details in unprecedented clarity. It is also said to minimises eye strain from long-term close-up viewing.

Because the manufacturing process does not use electroplating, reflow soldering or mounting, and because of VLED-II’s enhanced circuitry, optical and thermal design, VTRON says the dead pixel rate found in a LED-II display unit is much less than that in a conventional LED display.

VLED-II is said to offer the best performance lifetime ever for a VLED series. In a VLED-II display unit, the larger LED chip size delivers higher brightness with more even heat dissipation. Also, VLED-II is said to have almost no light attenuation, greatly prolonging the display lifetime and maintaining consistent brightness. Finally, VLED-II consumes much less power than that of a conventional LED videowall.