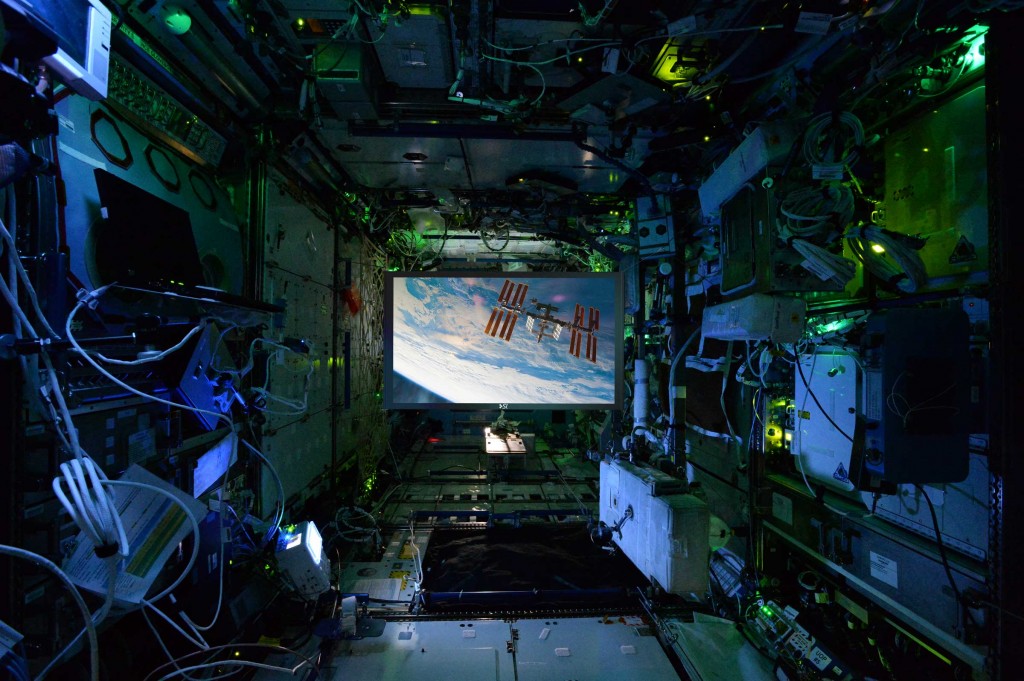

Screen Innovations (SI) has put the first projection screen in space, installing an ambient light rejecting zero gravity screen inside the International Space Station (ISS), to be used every day by astronauts and cosmonauts.

The screen installation coincides with a study into the effects of long-term spaceflight. The study started on 27 March, 2015 and sees one astronaut and one cosmonaut travel to the ISS and remain there for a year with a team back on earth studying the results. The astronaut involved is one of a pair of identical twins, which means the scientists have a unique opportunity to establish a control and achieve accurate results into the effects of zero gravity on the human body.

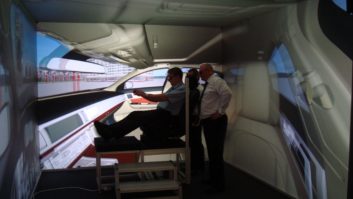

Before installation of SI’s screen, the only form of communication available to astronauts on the ISS was via tablet-sized, 13in displays. The larger screen will allow crewmembers to see images of their families that are closer to life-size. Another benefit of the bigger screen is for training and simulated operation of the ISS’s robotic arm and similar applications.

The ISS project took eight months and the SI engineering team faced a number of challenges, such as how to unroll and setup the screen as quickly as possible in zero gravity, and coping with the lights being on all the time. These challenges tested the team’s ability to deliver on a long-time SI motto: to provide “two-piece projection in any environment.” Ryan Gustafson, CEO of SI, said: “Space – it’s the ultimate environment. If we can put a screen there, we can put a screen anywhere on Earth.”

First, the ISS screen had to be constructed in such a way that it would be portable, and could be unrolled and made ready for viewing in seconds, in any module of the ISS. The final dimensions of the screen, when packed, could be no larger than those of a standard mailing tube for blueprints: roughly 3ft long, with a diameter of 2.5in. This immediately eliminated some screen materials – such as SI’s Black Diamond and FlexGlass, which can’t be tightly rolled.

SI has recently released a new ambient-light-rejection screen product: Slate. Designed to meet SI’s goal of bringing two-piece projection to any environment, anywhere, Slate was developed using what SI had learned from the creation of Black Diamond, but could be manufactured at far lower cost. Most important, Slate was a much more forgiving material that could be rolled up tighter and stretched out. After seeing a demonstration of Slate at SI’s world headquarters, NASA representatives all agreed that a Slate screen would be the one to go into space.

Work could now begin on the design and how the screen would be assembled. An SI engineer with a degree in aerospace engineering was familiar with a type of bungee cord developed specifically for and used by NASA. Using these bungees as the design’s centre point, the team quickly came up with a screen that could be rolled out by hand and attached in any cabin of the ISS modules.

“It functions somewhat similar to the way a motorised screen rolls out, but that’s where the similarities end,” said Robin Kampf, quality control manager at SI. “It is unlike any screen we have ever manufactured, and unlike any screen that any company has ever manufactured.”

After the first prototype screen had been built, SI travelled to NASA’s mock-up facilities in Houston, Texas. A projector manufacturer provided a new, 1080p laser projector for the project that uses a new laser light-source technology. Before the introduction of this new laser technology, the maximum lifetime of a projector’s bulb averaged about 3,000 hours. With a laser projector, a single bulb can produce zero image degradation for up to 30,000 hours, or about 3.4 years of constant use. The SI team deployed the screen and attached its four corners to the ISS module to display a 65in image floating in mid-air.

Screen Innovations’ space screens travelled to the International Space Station aboard SpaceX 6 on 14 April, 2015. “Working with NASA has been a dream come true,” said Ryan Gustafson. “But even though they are such a high-profile client, they received the same passion and innovation that we put into every product we make.”