The oil and gas industry makes extensive use of simulation and visualisation to minimise operational risks. Steve Montgomery reports.

In the oil and gas industry, nothing is left to chance and every attempt is made to minimise risk. Well-defined procedures are followed rigorously in all areas of the industry and especially in offshore situations. These include ‘Drill the Well on Paper’ or ‘Complete the Well on Paper’, workshops that bring together key participants in a project to go through the entire exercise on paper prior to a project. Computer-generated visualisations and training sequences that are unique to each project are produced and presented in conference rooms or auditoriums using large projection systems. On oil rigs, presentation rooms, which double as recreational film screening and meeting rooms, are used to display step-by-step animations of the procedures that will be completed that day to the crew.

Beau Brown, CEO of Industrial3D, is responsible for creating graphics, training and marketing videos: “Animated graphics can be used for a wide range of illustrative purposes and are often the only way of showing what is actually happening, or going to happen. Generally content is created as 3D illustrations shown on 2D screens, although 3D projection is used occasionally. Virtual reality is another interesting technique for creating walkthroughs of whole facilities to aid worker familiarisation. Touchscreens are useful for training, in the form of interactive kiosks and on touchtables for product marketing in the industry.”

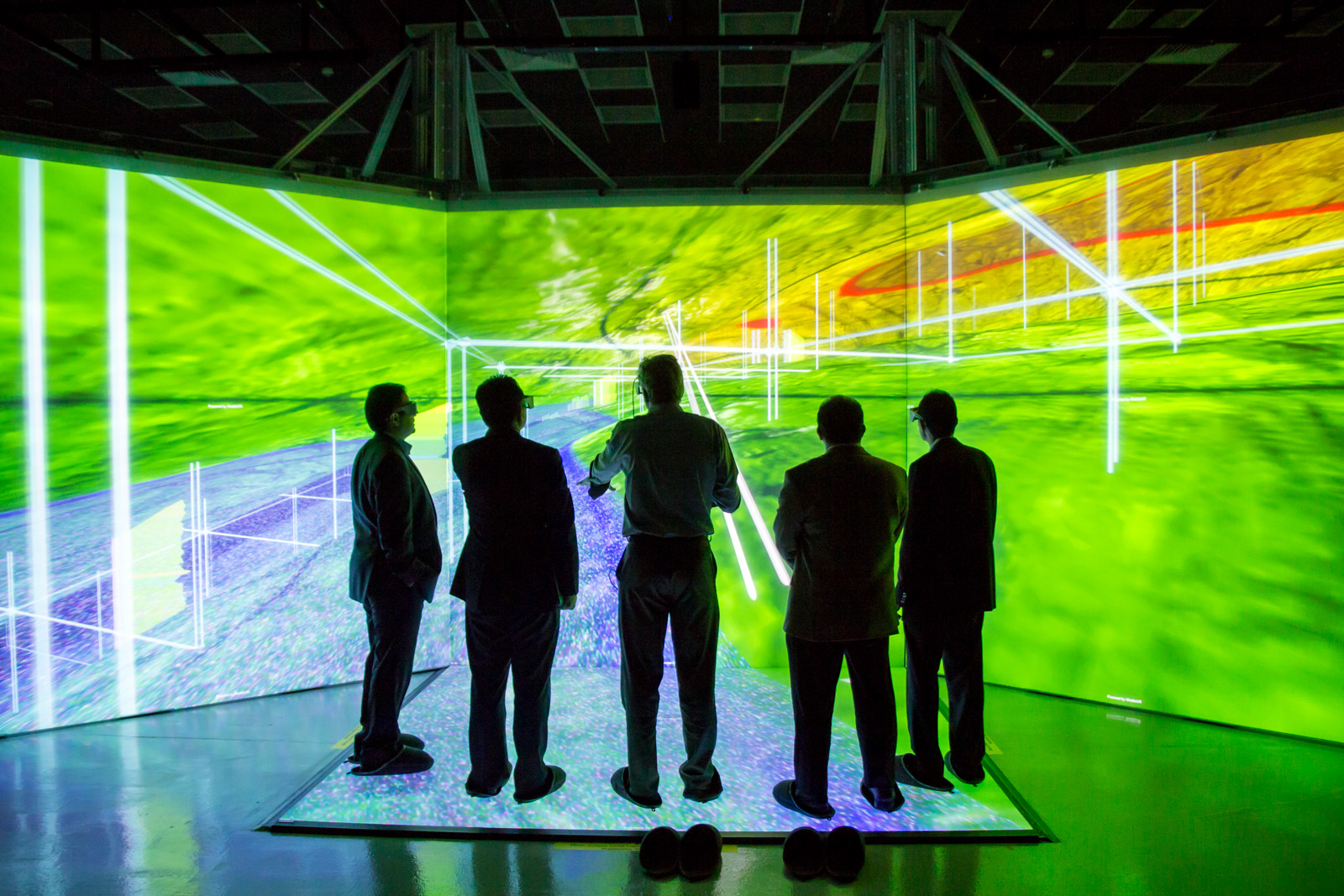

Aker Solutions has created a 180º 3D simulation dome with 11 high-resolution projectors to support ‘virtual engineering’ at its iPort integrated operations centre in Stavanger. “It has a dome-shaped training simulator, two Visioneering suites, a creative room and an IT technical facility centre,” explains Terje Fadnes, VP visioneering at Aker Solutions’ business area for maintenance, modifications and operations (MMO).

“The role it plays is in optimising offshore operations for complex installations, reducing non-productive time and testing and proving processes onshore in advance of real deployment. An example is in the development of a lifting procedure to move some heavy infrastructure: a crane operator in the dome works through the process, interacting with the simulated environment on the platform. A support team in the Visioneering suite can observe all the interactions on a large videowall that contains seven PIPs and optimise the actual procedure to be followed. They can see where obstacles are, and develop a procedure to navigate around them so that the risk of failure or damage is greatly reduced, while training the offshore crew for the real thing.”

Immersive simulation programs that use technology developed for computer gaming are ideal for training production workers, as Derek Middlemas, COO and head of enterprise solutions at engineering software provider AVEVA, explains: “The AVEVA Activity Visualisation Platform is built on industrial gaming technology and enables efficient facility familiarisation, staff training, plant construction planning and simulation, operations and maintenance planning. It aids the rehearsal of safety and schedule-critical activities, without putting personnel or the plant at risk, by generating realistic simulations direct from 3D design models, even before the physical plant has been built. Simulations are created directly from the plant’s original design model; they are visually convincing, realistic and accurate. Trainees can be immersed in a hands-on scenario and interact both with the model and with each other as avatars in a realistic virtual environment and can quickly become familiar with the plant.”

In the control room, graphical real-time visualisation is increasingly used on the main videowall and individual operator desks to deliver control and monitoring information. Sam Walton, UK marketing supervisor at software developer Iconics, explains the implications on display technology: “SCADA (supervisory control and data acquisition) devices communicate with control and monitoring equipment locally, on the same site, or remotely, providing central operation of global resources. The trend today is to present data in a more user-friendly manner so that everyone in the control room can see, and instantly understand it. The mass of data collected from an operational environment needs to be processed and presented rationally and intelligently. Processing and visualisation software is becoming more powerful, leading to higher data densities and more detailed imagery. This needs higher-resolution displays and image manipulation capability in the videowall controllers. Visualisations, including dynamic animated graphics, historical trends and geospatial grids are now available to plant controllers on their mobile devices as well as on the fixed displays in the control rooms.”

The growth in audiovisual technology across the industry offers scope for system integrators to become involved. “In the oil and gas market, a company’s industry reputation is very important to customers – it can be difficult for a new company to get an initial foothold,” warns Jed Deame, VP of marketing at RGB Spectrum. “It is very important for them to first cultivate strong relationships with oil and gas consultants to better understand the language of the market, figure out how to effectively position their services, and act as a point of contact to establish relationships with customers. The skills that will be most important to an integrator are the ability to visualise and design comprehensive systems for their customers. They must focus not on individual products, but on overall solutions that are tailored to meet the needs of individual customers. They need to understand the AV challenges, in both visualisation and control rooms, faced by oil and gas companies and focus on developing integrated solutions that address these concerns.”

The oil and gas industry is massive – it is estimated that over $1 trillion is invested in exploration and production annually – and requires significant amounts of AV technology, in its finest and most advanced forms. Opportunities for integrators abound in all areas of the industry, at all levels, and with commitment, it could be a good match for professional AV and IT specialists.

www.akersolutions.com

www.aveva.com

www.iconics.com

www.industrial3d.com

www.rgb.com