As part of our special report on major projects, we’re looking in depth at how a number of major AV installations were organised and managed. Here, Tim Frost reports on the Maersk Tower, a 15-storey, €200 million building, which contains the world’s largest Meyer Sound Constellation system in an education facility.

The Panum Institute’s Faculty of Health and Medical Sciences at the University of Copenhagen is housed in the new 15-storey Maersk Tower, which was officially opened by the Queen of Denmark in January 2017.

All AV systems at the DKK 1.5 billion (€200 million) research and education facility were designed, engineered and installed by Stouenborg ApS of Copenhagen, under the supervision of project leader Anders Jørgensen. This comprised fitting out four auditoriums, 100 meeting rooms, 16 100-person education rooms and four conference rooms – as well as 50 signage displays and 100 room-booking screens.

The building itself was in the hands of a governmental agency, but the A. P. Møller Foundation, a major funder of the building, determined that it would take on the entire responsibility for the AV systems and then gift it complete to the university.

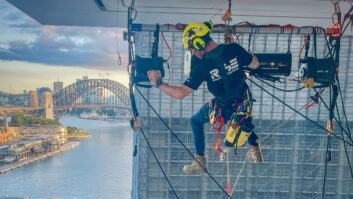

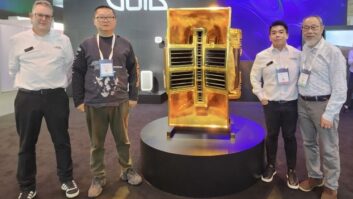

Three of the auditoriums have Meyer Sound Constellation electroacoustic systems – making the Maersk Tower the largest education-focused Constellation installation in the world by some distance.

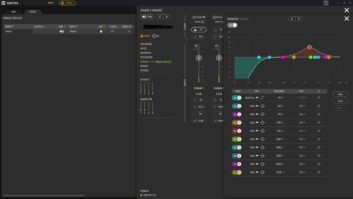

The largest auditorium has a capacity of 550; it has been equipped with 89 microphones, 124 loudspeakers and 19 networked D-Mitri frames, including core processing, D-VRAS and input/output. The other two Constellation auditoriums, seating 220 and 120, have systems with 32 microphones and 97 loudspeakers; and 32 microphones with 88 loudspeakers respectively.

More than 22km of cable was installed for AV throughout the building – mostly Cat6a to support networked applications and to provide a degree of futureproofing. The AVB protocol is used for the Meyer Sound D-Mitri as well as the Biamp Tesira system used for auxiliary systems and smaller rooms. Other major items of AV include Panasonic displays and projectors, a 4K Crestron DigitalMedia system, ONELAN media players, and wacom touchscreens connected to a master PC.

Templated elements

While there is no ready-made overall template for a large project like this, says Jørgensen, “we template for elements such as the way we do cabling or racks, and how to test things. You can copy-paste the backbone and the project management processes with things we have learnt from previous jobs. But it’s impossible to have a single overall template with a big project like this as they are all so different.”

This was Stouenborg’s largest single project in terms of scale and complexity, which presented challenges.

“From a technical standpoint it is not hugely different. Instead of doing one auditorium we have four auditoriums, which means just addressing more of the same problems. The real complexity is in the logistics – securing supplies and the people to do the work. Planning errors on a large project can really kick in and you really need plan the next five steps ahead at least.”

Stouenborg was deeply involved with defining the technical environment. Early discussions revolved around how technology will support the learning environment for the next decade. “We had a lot of discussions about aspects like TEAL (technology-enabled active learning). There are lots of new learning forms to reduce the distance between the professor and the student and this makes it easy to interact, even in a big 500-seater auditorium – that’s where the Constellation system came in.”

Since the Foundation was commissioning the project, Stouenborg could change the specification to include newer, better technologies when they became available. “The project started in 2014 and completed in 2017 – that’s a hell of a long time. If this had been a public tender then they would have been stuck with the older products and technologies – so we would have had HDMI rather than an IT infrastructure. We actually changed the video system three times during the project.”

Novel solutions

With a build of this scale it made sense to look for some novel project solutions.

“We had 2,500 network lines of more than 40m length, so we bought a tool to test network cable. It cost around £10,000 but then we weren’t chasing ghosts when there were problems. On a smaller scale we optimised our soldering process with a £200 system that saved 40% of our soldering time for the 10,000 solder points on this project.”

Did the project run smoothly? After a pause, Jørgensen explains how to manage an installation when, due to a number of issues, the building in which it is located ends up being completed well over a year behind schedule.

He focuses on the impact this had on the personnel involved. Stouenborg substantially expanded the pre-assembly and testing systems, moving the work and its people back to the warehouse. “We set up 16 education room systems with projectors and everything – loaded and tested them for months, ensuring that all the programming was done. That also meant we reduced one of the things that really takes time: sorting faults on site.”

Stouenborg believes in building a strong relationship with the pool of additional people it draws on for bigger projects. “In reality that means we can scale back up more easily because we have created a strong connection between the company and the employee. The most important resource is your people; companies that don’t understand that won’t be in business for long.”

Looking back, what was the main thing Jørgensen learned? “We learned a lot about preparation and that planning is the key to everything. Every time you don’t plan and don’t look three or four steps ahead, you lose it, and you see that on the budget and the timescale.”