Innovation within the LED industry is thriving, pushing display performance capabilities to new heights. The resolution, pixel pitch and brightness will always be the key specifications for integrators and end users to consider during purchasing decisions. However, as display sizes increase and pixel pitches decrease, buyers need to understand the impact sub-1mm pixel pitches have on the broader LED features and which technologies are the ones to watch.

Innovation within the LED industry is thriving, pushing display performance capabilities to new heights. The resolution, pixel pitch and brightness will always be the key specifications for integrators and end users to consider during purchasing decisions. However, as display sizes increase and pixel pitches decrease, buyers need to understand the impact sub-1mm pixel pitches have on the broader LED features and which technologies are the ones to watch.

LED technology is incredibly sustainable and versatile, and these are just two of a long list of beneficial features. As pixel density increases, some classic challenges are exacerbated and some new challenges arise.

FIRST FACTORS

Heat increase, colour shift, brightness levels and durability are often the first factors to be compromised as the pixel pitch narrows. We see these issues frequently occurring in displays using traditional manufacturing and connection processes. It’s almost impossible for any display using the Common Anode connectivity method to reach sub-1mm pixel pitches without suffering from poor performance, higher running costs and reduced lifespan. This is due to the excess heat being generated which ages and degrades the LEDs.

Power and heat savings are required for sub-1mm displays to operate efficiently, which is why developing new manufacturing processes is crucial for the evolution of the LED display market. Flip Chip, Chip on Board (COB), and Common Cathode are the main elements in the race to produce MircoLEDs and MiniLEDs, but it will also require the support of durability technologies to enhance the overall display performance.

COB is a cost-effective process which eliminates LED packaging, reducing the required real estate and therefore allows for higher pixel densities. Whereas Flip Chip is an energy saving manufacturing process that improves heat dissipation and reduces power consumption, while unlocking the higher brightness capabilities and improving viewing angles. Flip Chip is the way forward for sub-1mm display, but it is still developing in stages and requires further improvements before we see an efficient sub-0.7mm display.

COOL TOUCH

To reduce excess heat, Common Cathode LEDs are essential to keep display operating temperatures cool-to-the-touch, especially in tighter pixel pitches. Common Cathode technology powers the LEDs more efficiently by supplying dedicated power voltages to each LED. It’s the only way to control all power voltages to eliminate heat wastage at the PCB level.

Solutions such as IMD are also being introduced to the market to combat the power/heat challenges. Depending on the LED packaging, visual anomalies can occur. Uniformity becomes increasingly challenging as smaller pixel sizes and tighter pitches are being introduced, especially in the sub-0.8mm category.

While the demand for displays with ultra-fine pixel pitches with flawless visual appearance and cool operation rises, it’s also crucial to understand the impact on durability. The smaller the pixel pitch becomes, the more it is subject to damage. Therefore, an advanced method of protection is required that will increase the durability whilst ensuring the display remains serviceable at PCB level and preserves the characteristics. For this, it’s best to select a screen that uses an LED encapsulation technology, such as LISA.

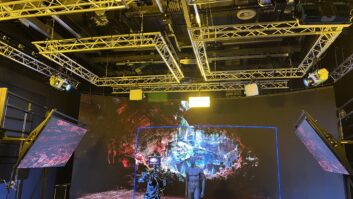

These emerging technologies will open the LED market to new applications and transform how LED display technology is utilised for the better.