Eight months after landing the job of running the renowned manufacturer and on the eve of a major launch at Prolight + Sound, Martin Audio managing director Luke Ireland talks to Paddy Baker about addressing the installation market and easing the company’s growing pains.

What was your impression of Martin Audio before you joined – and did it change at all afterwards?

My impression was that it was and is a premium audio brand with a very good reputation for innovation and product design. That hasn’t changed since I joined: we’ve made some improvements in customer service and operations, but the core values of the company remain the same.

What aspects of your experience in previous roles have you found most useful at Martin Audio?

Martin Audio has grown four to five times in size on the back of MLA [launched in 2010], and has had some growing pains associated with that. That’s something I’ve managed in the past several times, either being part of that growth or joining a company when it’s reached a certain level and needs a new set of eyes. That’s really where my operational and sales leadership skills have come in to Martin Audio. The company has reached a certain level and needs a new level of management to take it to the next stage of its development.

What have been the key focuses of your attention since taking over?

We’ve made some significant changes to operations since I joined. For many years Martin Audio was a business that made very high-quality but relatively simple speaker systems. MLA is a high-technology product, and things needed to change to put it on a good platform for growth. The changes have been around operational efficiency and change – including lean manufacturing – enhancing our customer service proposition and also growing our sales, particularly in the US market where we see a strong opportunity for us.

Tell me about lean manufacturing.

Fundamentally the change that we’re making in High Wycombe – it should be completed by June – is to move from a batch build, where you make 100 or 500 of a product at a time, to single-piece flow, where you can make one of something with the same efficiency as batch manufacturing. We have quite a wide product range and we want to be able to react quickly to customers’ demands on things like colour or configuration. So the ideal for us is to have levels of inventory so we can ship on a next-day basis, but also to have very a rapid lean manufacturing facility that enables us to build to customers’ orders very quickly on a batch size of one.

The key thing is to get rid of what we call non-value-adding steps in the manufacturing process: at a basic level, the time it takes to go and get a screw from a shelf is non-value-adding, putting that screw in the product is value-adding. We’re making the staff more efficient and at the same time expanding the workforce, to give us a platform where we can grow the next stage of the business without massively increasing our overheads.

So does the factory floor look very different now?

It does. We’ve rearranged the whole of manufacturing: we’re running a very clean ‘5S’ system for assembly where everything has its proper place, everything gets returned to its place and you can immediately see if something’s not where it should be. There are regular team meetings around production planning, so there’s more of a collaborative effort, and that’s resulted in a completely different production environment. It’s gone away from 10 people building a load of products to each person building one product, but still working in teams.

Would you say the installation market is growing in importance for Martin Audio?

Absolutely. The MLA technology has been in the touring and live sound markets for quite some time, but we’re starting to see it increase in the installation market. But whether it’s MLA or more standard installation products, we see this market as a massive growth opportunity for us, particularly in the US where we’re focusing some additional sales effort. MLA is winning us business in acoustically difficult environments such as churches and concert halls, and we’re launching a new range of products in Frankfurt using a new technology that we believe will revolutionise the sector of the installation market that delivers most volume.

Do you think the overall installation market is growing, or is it just that your solutions can get you a bigger piece of the pie?

The US market is the strongest in the world for installations, and in the houses of worship market, the type of activities have changed: it’s gone from a traditional church environment to performing artists and bands, and that requires a different level of installation. So the market is growing and the complexities and requirements are growing at the same time.

We’ve just done an installation in New York in a big glass atrium. You can imagine the acoustic issues around that – historically no-one would have attempted an installation in that environment, but with our technology they were able to. So we’re seeing two things: a change in people’s requirements, and technology enabling installations in environments where they previously wouldn’t have been possible.

Installation is less of a focus for us in some countries than others. The European market for installations is growing; Asia is relatively lower on the curve in terms of opportunity, but we see growth everywhere.

What are the synergies that arise from being in the touring and installation markets?

MLA technology, which was originally developed for live and touring, is winning business for the installation market – people are hearing it demonstrated or as part of a live sound experience, understanding what it can do and realising that they can do things in installations that they couldn’t previously have done.

Recently we had a big tour in the US with Steely Dan – arguably one of the most demanding bands in the world acoustically. Their tour was very successful and has provided the catalyst for a lot more interest around MLA technology, and that has borne fruit with a number of installation projects that we’ve won – on the back of that tour basically.

It sounds like MLA is a very large part of Martin Audio’s business.

MLA is a relatively high-cost product compared to our standard AQ system, but we might sell one MLA Mini system and 100 AQ series speakers. So in terms of units it’s much lower than our standard installation products, but in terms of revenue it’s about 40%; the standard installation business is still the majority of our business.

Do you think there are too many loudspeaker manufacturers in the market?

Yes, there should just be us! There’s lots of competition out there at different levels of quality and price. We compete at the upper end, aimed at high-quality, performance-driven products. There are always going to be customers who are price-driven, so there’s a market for other manufacturers there. There’s a declining number of players in the market that people actually consider, so I think the market’s about right – though a few more may fall out over the next several years.

What were your impressions of ISE?

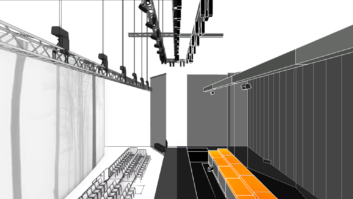

We had a very successful ISE – it was the first one where we had a separate product demonstration area, about 10 or 15 minutes from our booth. We had six sessions: prior to the event we had 100 people register to attend, and by the end we had had 350. I know as the MD I should say this, but it really was very impressive. It’s great to work for a business where you think, “Our product sounds fantastic”. And the feedback from the customers was the same – over 90% of people said they would recommend Martin Audio on the basis of that demonstration.

ISE is slightly unique in the tradeshow world in that it’s addressing a growing and very rapidly evolving sector – so a show like ISE is vital for that area of the industry. In other industries I’ve been in where the pace of change is lower, it’s less important – but for ISE, given where that sector of the market is now, the whole area of rich media delivery, it’s changing so quickly that if you’re in that business you need to be at ISE to get an overview of the market.

You’re not tempted to ‘do a Harman’ and move into video or lighting?

No. We’re an audio company – the clue’s in the name. There’s plenty of market for us, and we have an engineering team who are all audio-focused engineers. [Moving beyond audio] isn’t something for us.

Martin Audio has launched a teaser campaign about the installation product that you’ll be launching at Prolight + Sound – what can you tell us about it here?

The core technology isn’t necessarily limited to the installation market, although we will launch it for the installation market first. It is a complete step-change in driver technology – there’s nothing else like it on the market, it’s patented technology and we are very convinced that it will be met with a lot of interest from our customers and our competitors. It’s a major launch for us.