European consortium Optintegral, which comprises nine partners from five European countries, has developed a mould-based hybrid manufacturing technology for LED screens that not only reduces costs and time-to-market by 40%, but also halves the harmful emissions produced during the manufacturing process.

The research received funding from the EU’s Programme Horizon 2020 project and was created to find new sustainable TOLAE (thin, organic and large-area electronics) displays that are cheaper, thinner and environmentally efficient.

The project, which began in 2015 and completed in January, addresses the need for sustainable industrial manufacturing processes of LED displays, specifically responding to the market’s technological demand for simpler device integration by efficient and low-cost manufacturing methodologies.

The new technology developed within the project’s framework is to be presented during Optintegral’s Technology Innovation Conference and Showcase, taking place on its stand tomorrow.

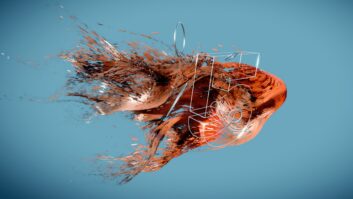

The partners will demonstrate three prototypes at the conference and showcase: a large-scale, high-resolution 2D screen with lighter and finer backlighting than the models currently on the market; a flexible, large-format, super-thin RGB screen that is 50% thinner than its standard competitors; and a high-density 3D screen with a new lens system that makes it possible to create a 3D effect without special glasses.

It is anticipated that this range of devices could be brought to market within a year, giving users the opportunity to take advantage of the economic and energy-consumption benefits of the flexible, large-format printed electronics used in TOLAE technology.