With demand for videowalls booming across the sectors, Rob Lane looks at the various challenges that mount manufacturers are looking to address in their product development programmes.

Mounts and brackets manufacturers are reaping the rewards of a boom in digital display specification across several sectors, with increased demand for videowalls having a major impact on bottom lines. Peerless-AV Europe recently recorded its ‘best ever’ sales and Chief has been investing in new resources throughout the first quarter of 2016.

The popularity of videowalls has, in part, been as a result of LED’s falling costs and shrinking pixels, with virtually non-existent bezels adding to the technology’s desirability for videowall specification. Of course, ever-larger videowalls and a broadening of their uses add to integration challenges, giving mounts manufacturers new problems to solve. They are, it appears, up to the challenge!

Challenge 1: The need for three-dimensional alignment

Vogel’s PFS 3504 top-adjustable display strip can be adjusted in three directions (3D – horizontal, depth and tilt) and has a vertical fitment of 400mm. Once a display is in place, the strip’s built-in service position makes it possible to easily connect cables. The service position also allows each individual display to be removed for maintenance or replacement, even if the display is situated in the middle of the videowall. Additional features include a lock for lateral shift to avoid horizontal movement, and an optional padlock (PFA 9109) protects against unauthorised removal.

“Because we always have to deal with tolerances in the wall, supports and displays, we designed a 3D-adjustable interface display strip,” explains Jannine van den Akker, marcomm co-ordinator, Vogel’s Professional. “3D means height, depth and tilt adjustment. With these features it is possible to achieve an overall seamless and flawless look.”

Challenge 2: Demand for speedy installation

The Peerless-AV DS-VW755S Ultra-Slim model (48mm side profile depth) is a ‘quick, intuitive and hassle-free solution’ for creating a discreet videowall array close to the wall. The mount pops out to extend its display passenger from the wall into a negative tilt position to assist with fast set-up and easy access to the rear, and beneath the display for servicing.

Reusable custom wall plate spacers eliminate the need to calculate and measure the position of each mount in an array, while eight-point tool-less micro-adjustment provides all the necessary fine-tuning for seamless display alignment with the rest of the videowall. The DS-VW755S’s keyhole slot wall plate design and Peerless-AV’s Video Wall Mount Locator App further simplifies installations.

“Our Full Service Quick Release Video Wall Mounts cleverly deliver up to a 60% reduction in installation time,” says Gordon Dutch, managing director, Peerless-AV EMEA. “For this reason they are widely trusted by installers for today’s complex and challenging digital signage applications.”

Challenge 3: Accessing an individual display in the centre of an array without dismantling the whole wall

B-Tech’s BT8310 mount is a tried and tested solution for accessing that difficult centre screen of a large videowall. It has been used in installations around the globe, from control room projects to retail displays.

A single push and release system gives integrators fast and easy access to screen fixings and connectivity, making light work of maintenance and/or replacement of displays. In addition, the mount’s pop-out mechanism features a rigid design, allowing it to pop straight out/in with virtually no lateral movement, preventing screen edges from clashing during the movement. B-Tech sees this as particularly beneficial with today’s displays having virtually no bezel and being susceptible to damage if impacted at their edges.

Mark Walker, global business development manager for B-Tech AV Mounts, says: “Such is the popularity of the bracket that we have recently integrated this ‘pop-out’ technology with our System X range and will be launching this to market very soon.”

Challenge 4: Mounting on difficult wall surfaces such as stud walls

Weight distribution, not just display weight, is critical when mounting onto difficult wall surfaces. Chief recommends its LVS1U ConnexSys series videowall mount, which ships fully assembled with wall-mount rails attached to the mounts.

LVS1U can be used like a conventional videowall mount, but Chief recommends the use of long standard 41mm rail channels for larger videowall matrixes.

“The most difficult wall surface is of course an end-user request for a videowall where there is not a wall present,” explains Robert de Jong, product marketing EMEA, at Chief. “We have seen large-scale projects where end-users and installers requested all the mount solution features of a front serviceable mount in mid-air locations! The new Chief videowall mounts have been designed with exactly this common installation issue in mind.”

De Jong adds that the LVS1U allows for easy videowall preparation with material installers have access to on ‘a daily basis’. This enables system integrators and installers to prepare the job-site before the mounts and the displays arrive. “It also eliminates the need for horizontal wall mount spacers and horizontal measuring, and levels out the first ‘slope’ in the wall construction,” adds de Jong.

Challenge 5: How to get around the lack of a universal standard for LED

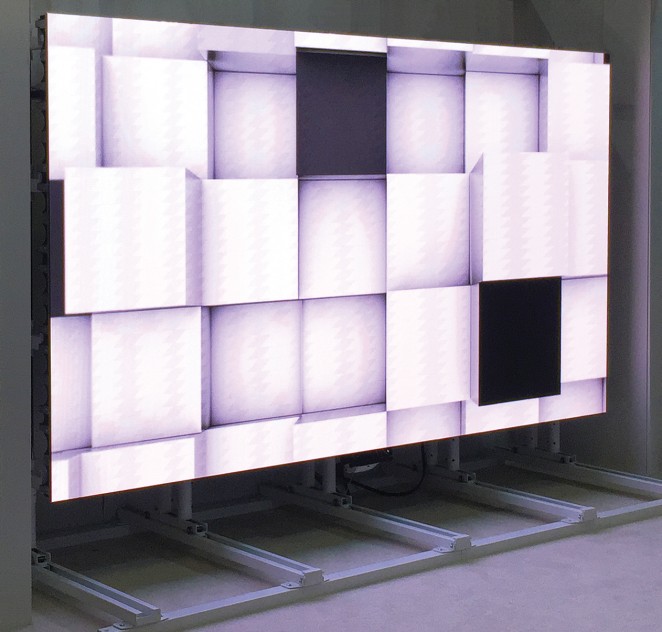

Small-pitch LED panels may be growing in popularity for videowalls, but as yet there is no universal standard of fixing patterns between LED panel manufacturers. Unicol, however, reckons it has found a way of getting around this particular issue. Its VLED system utilises a custom-built unit that interfaces with LED cabinet fixing holes. Several units can be connected to a lattice structure to build an array of accurately aligned LED panels.

As these LED panels are made up of smaller tiles, which in many cases are fixed to the panels’ chassis magnetically from the front, replacement is easy once the system has been installed. And Unicol’s Roller-Trak system allows easy front access for those times when an LED wall is facing a shop window, for instance.

“We are designing solutions not just to be wall mounted but floor to wall/ceiling, freestanding, ceiling suspended and rolling units,” explains Rachel Hunt, Unicol marketing director. “This means that our latest LED mounting solution, VLED, interfaces with current Unicol mounting structures, making it adaptable for all installations.”

Challenge 6: Working in location where only front access is possible

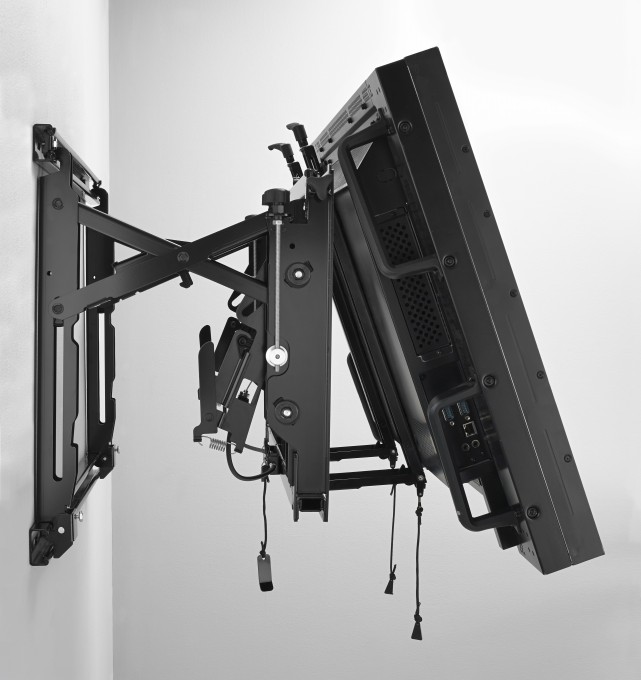

Designed and manufactured in Poland, the VWPOP65 is available in landscape and portrait configurations, and in a larger 95in option. It was designed for ‘easy and fast’ delivery of recessed multi-screen installations, and includes tool-less micro adjustment allowing horizontal, vertical, depth, tilt and rotation adjustment.

A one-touch pop-out mechanism allows full extension of the display from the videowall, so access and servicing can be performed quickly and safely from the front.

“What sets the VWPOP65 apart is its ease of installation,” says Gregory Bak, sales director at Edbak. “As well as precision dedicated spacers, which eliminate the requirements for on-site calculations and measurements, the VWPOP65’s standout feature is its tool-less micro-adjustment system. For the time-pressed installer, instant access to micro-adjustments in five dimensions is a huge benefit.”