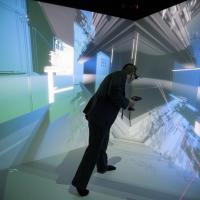

A new Virtual Reality suite at the Manufacturing Technology Centre (MTC), Ansty Park, Coventry, UK uses four projectiondesign F35 AS3D active stereoscopic 3D projectors in a rear and front projection CAVE (cave automatic virtual environment) solution. Installed and designed by virtual reality specialists HoloVis International, the system is designed for UK manufacturing businesses to naturally visualise 3D prototypes of manufacturing facilities and processes before bringing them into the production process.

Inside the Virtual Reality suite at the MTC, the F35 AS3D projectors are positioned using rear and front projection and fitted with specially designed distortion-free projection lens technology to deliver detailed and accurate images. The HoloVis CAVE incorporates the latest IR camera-based motion tracking technology to track the user’s head position and orientation. The system then generates real-time 3D visuals for the user’s perspective, providing the most natural interaction with the virtual world. An input wand device also allows for natural human interaction within the computer datasets at all times. The system had to be specially designed into the existing MTC facility and HoloVis manufactured the CAVE structure and projector rigs to accommodate the limitations of the space available for the solution, whilst ensuring that there was no compromise in the technical setup.

“We needed a system that could handle any kind of 3D content, and which allows the user to get close to the projection surface,” said Jonathon Shaw, technology manager, MTC, “whilst maintaining a good resolution, a critical requirement for a fully immersive system.”

“The system is designed to enable UK manufacturers to visualise complex, three-dimensional processes,” said Stuart Hetherington, managing director at HoloVis International. “The F35 AS3D projectors were selected because of their small size, overall build quality and reliability as well as their optical performance. The technology is backed up by excellent installation and engineering support from our projection partners projectiondesign.”

“The Virtual Reality suite enables informed decision making prior to the commitment and expenditure of building a physical prototype,” said Clive Hickman, CEO of the MTC. “Multiple iterations can be viewed in context. Concepts through to complete solutions can be investigated and analysed rapidly and early within the design process to ensure costly mistakes are avoided, empowering development stakeholders to focus confidently on their key objectives. The diversity of applications in which the system is used is virtually limitless, including: the interrogation of new-product designs; the detailed analysis of the evolution of weld joints; the development of procedures associated with a new manufacturing facility. The installation of the Virtual Reality suite adds value across core research themes and yields great benefits for MTC’s stakeholders and members’ research and commercial interests.”

“The F35 AS3D projector was created to address the installation requirements and demands of virtual environments,” said Anders Løkke, marketing director at projectiondesign. “It comes with 1,900 x 1,200 resolution at 120Hz refresh rates and the ability to display 3D video content. For total accuracy the RealColor colour management software facilitates onsite calibration to deliver accurate images. As well as the specially designed lenses, MTC can fine-tune the image through its Smear Reduction Processing that is said to minimize motion artefacts to reproduce superbly detailed images.”